STAPLE

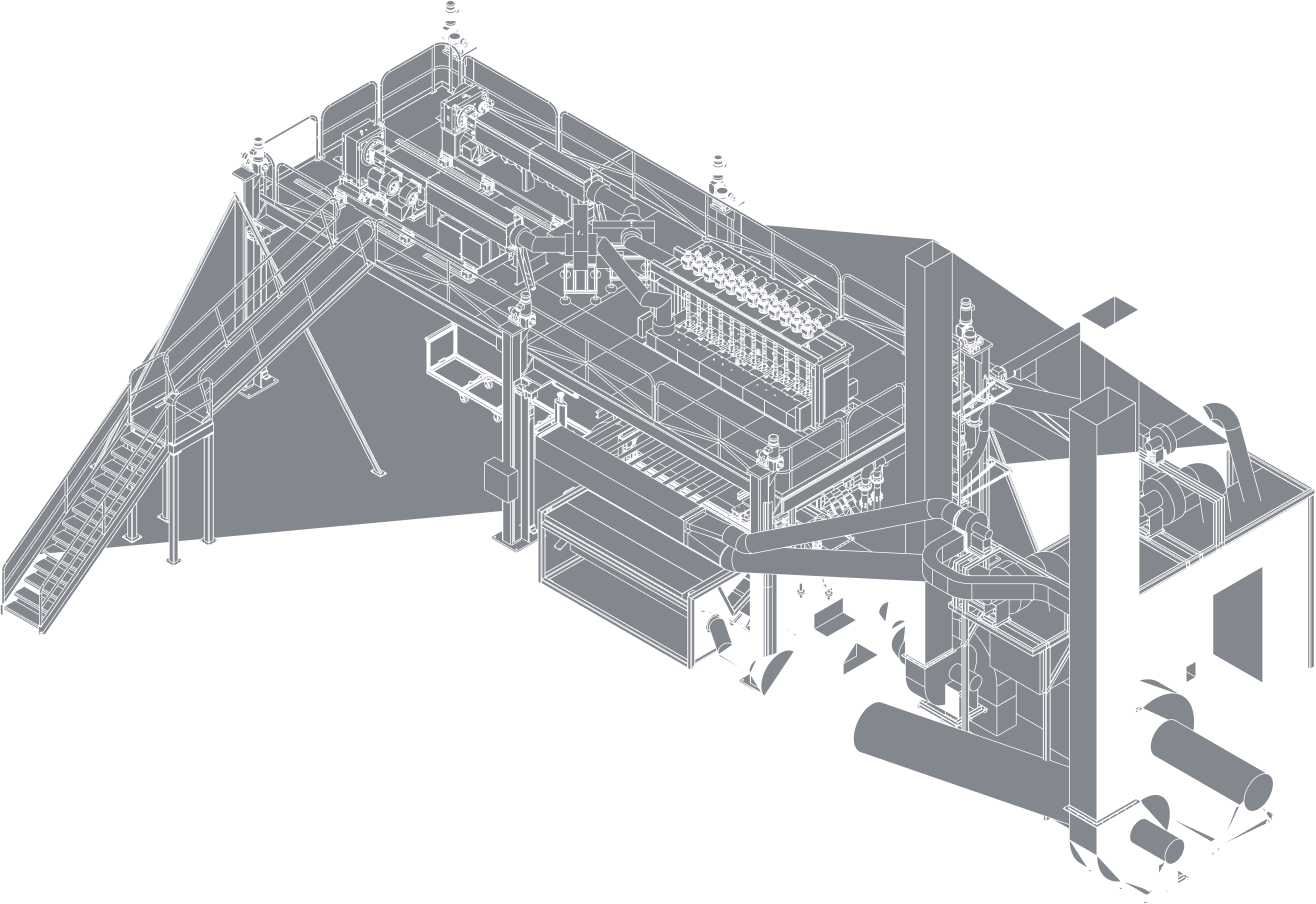

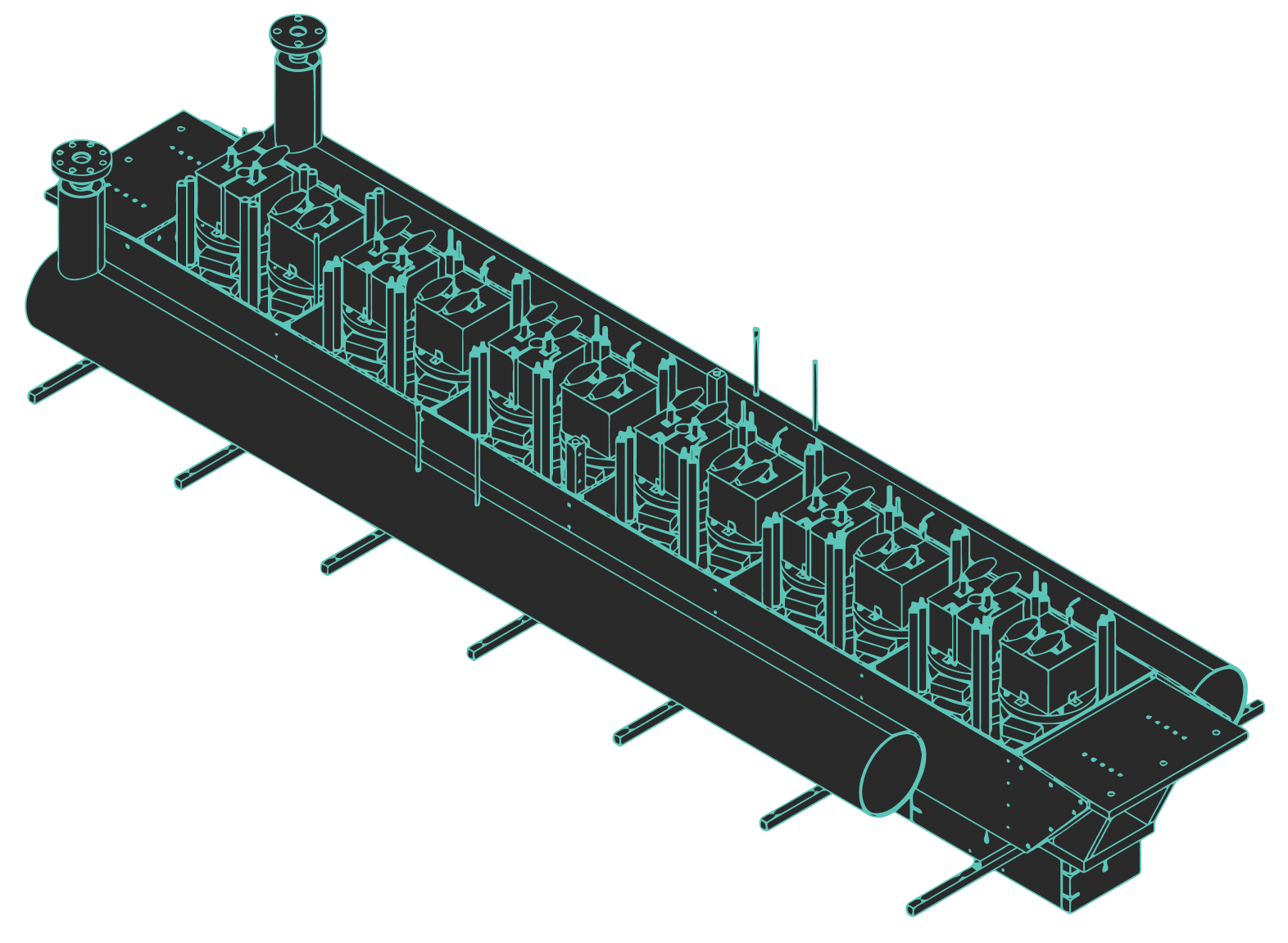

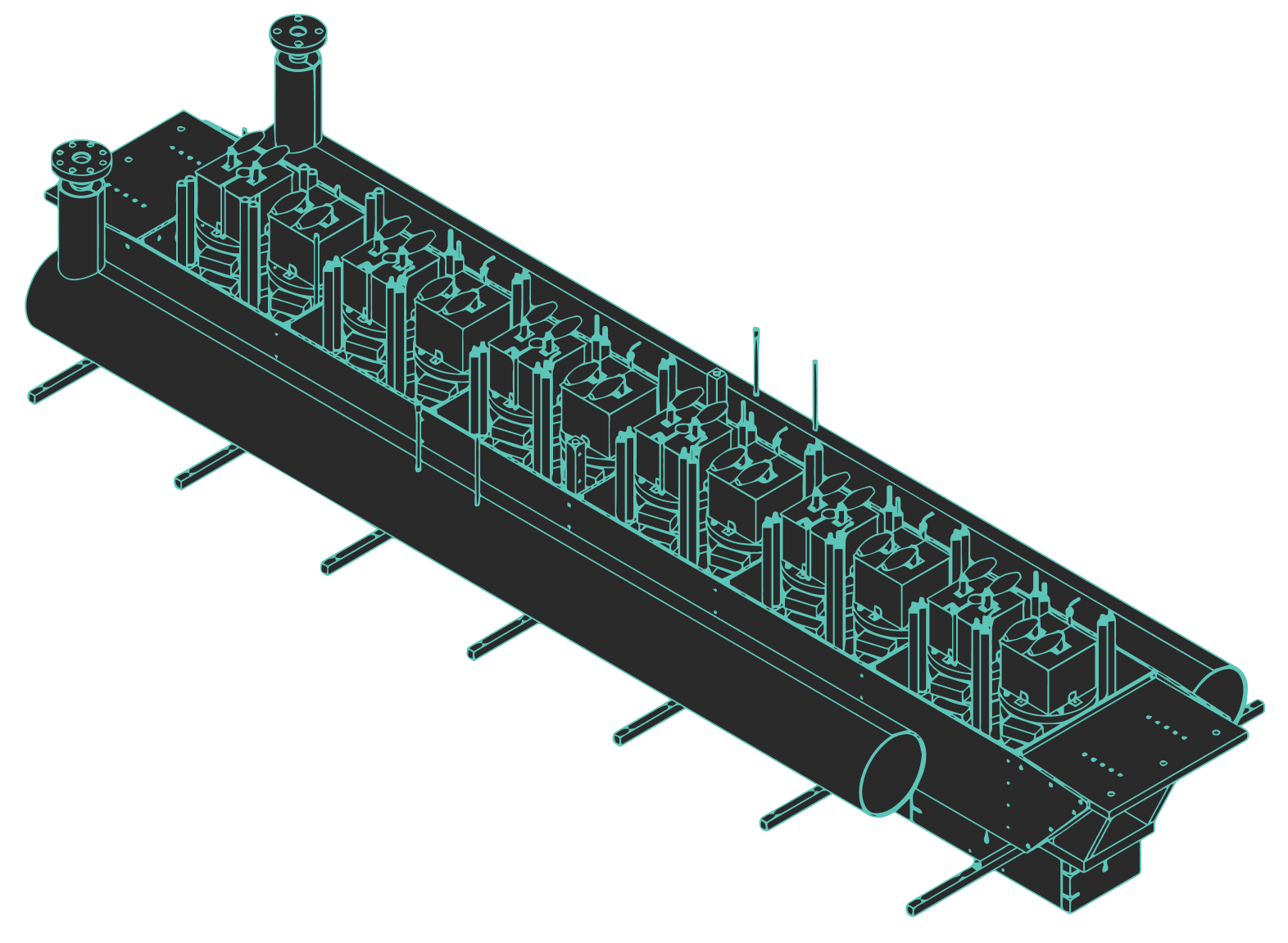

Hills Inc.'s custom Staple fiber systems enable the production of high-quality, short-cut fibers using a multi-step process that ensures consistent fiber properties and performance. By extruding molten polymer through a spinnerette, drawing, crimping, and cutting the resulting filaments, Staple fiber technology creates versatile fibers for a wide range of applications across various industries.

CUSTOM SYSTEM DESIGN

The design of our systems allows for customization of key components, such as spinnerettes, drawing units, and crimping devices, enabling the production of Staple fibers with tailored properties for specific end-uses.

Hills' Staple fiber equipment is engineered to process a variety of polymers, including polypropylene (PP), nylon (PA), polyester (PET), and other specialty polymers, while maintaining precise control over critical process parameters.

- Polypropylene

- Polyamide

- Polyethylene Terephthalate

END-USES

REAL-WORLD PRACTICAL APPLICATIONS

- TEXTILES

Apparel, home furnishings, and industrial fabrics

- AUTOMOTIVE APPLICATIONS

Sound insulation and trunk liners

- FILTRATION

Media for air, liquid, and oil filtration

- CONSTRUCTION

Concrete reinforcement, roofing materials, and erosion control

WHY

CHOOSE

HILLS?

Unlimited potential for varying polymer distribution i.e. cross-section profiles and ratios, within the fibers enabling customization and versatility.