SPUNBOND

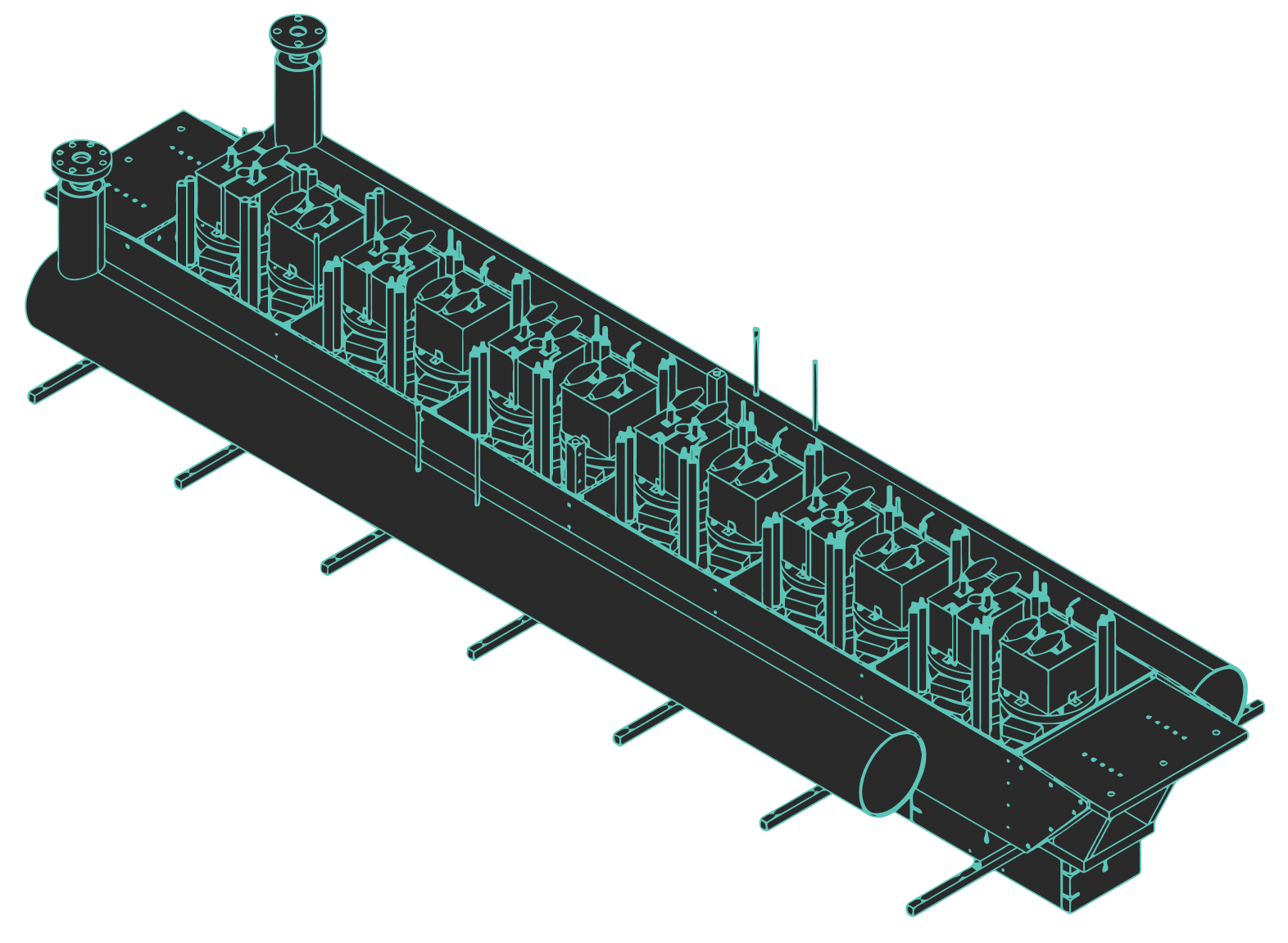

Hills Inc.'s custom Spunbond systems enable the efficient production of high-quality nonwoven fabrics using a continuous, one-step process. By extruding molten polymer through a spinneret and bonding the resulting filaments, Spunbond technology creates strong, durable, and versatile nonwoven materials for a wide range of applications.

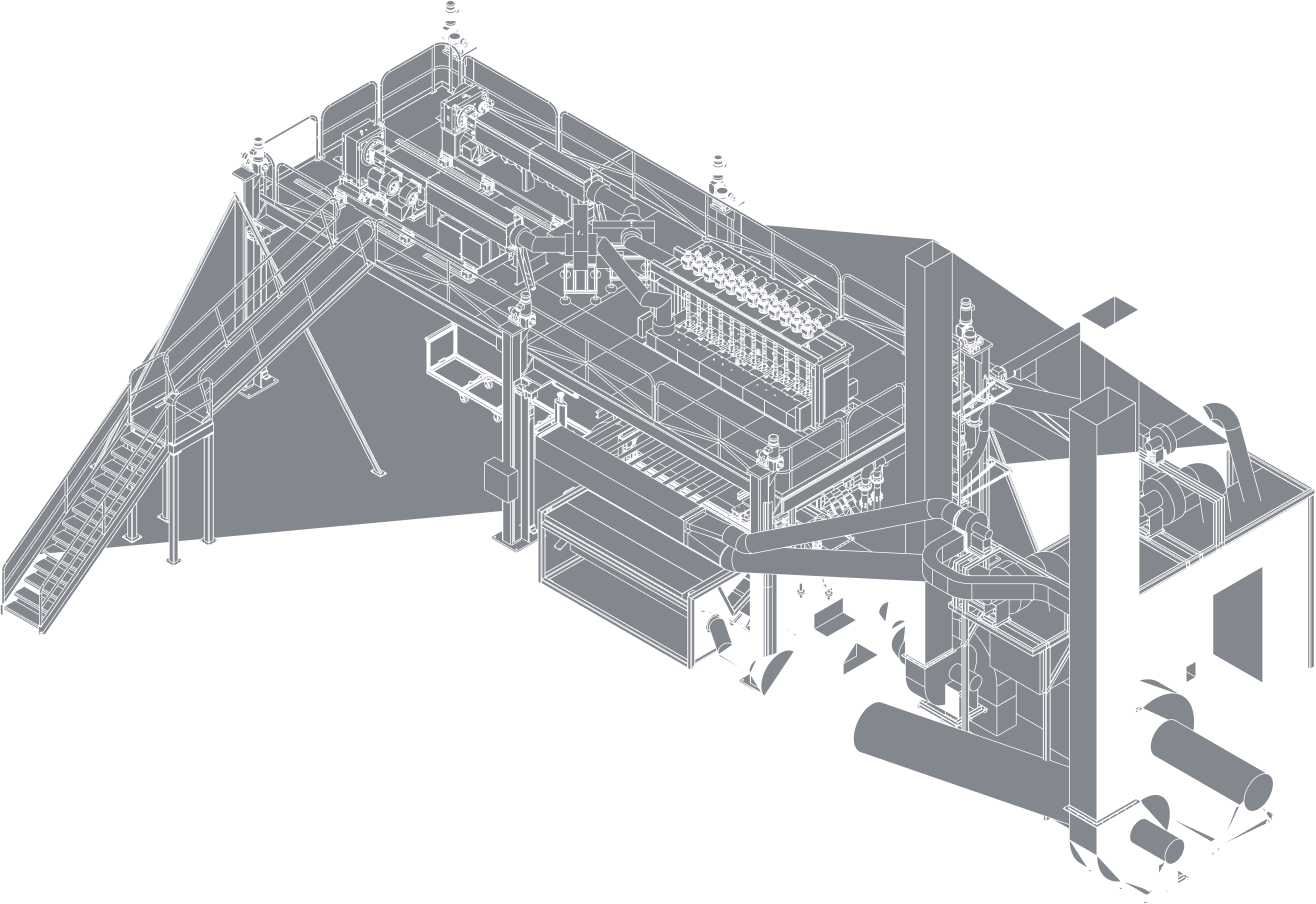

CUSTOM SYSTEM DESIGN

The modular design of our systems allows for customization of key components, such as spinnerets, quenching systems, and bonding units, enabling the production of Spunbond fabrics with tailored properties for specific end-uses.

Hills' Spunbond equipment is designed to process various polymers while maintaining consistent fiber quality and web uniformity. In addition, new and upcoming textile grade bio-polymers can also be processed.

- Polypropylene

- Polyamide

- Polyethylene Terephthalate

END-USES

REAL-WORLD PRACTICAL APPLICATIONS

- MEDICAL DISPOSABLES

Surgical gowns, drapes, and sterilization wraps

- GEOTEXTILES

Soil stabilization, erosion control, and road construction

- AUTOMOTIVE APPLICATIONS

Carpet backing, trunk liners, and air filters

- AGRICULTURAL COVERS

Crop protection and weed control fabrics

WHY

CHOOSE

HILLS?

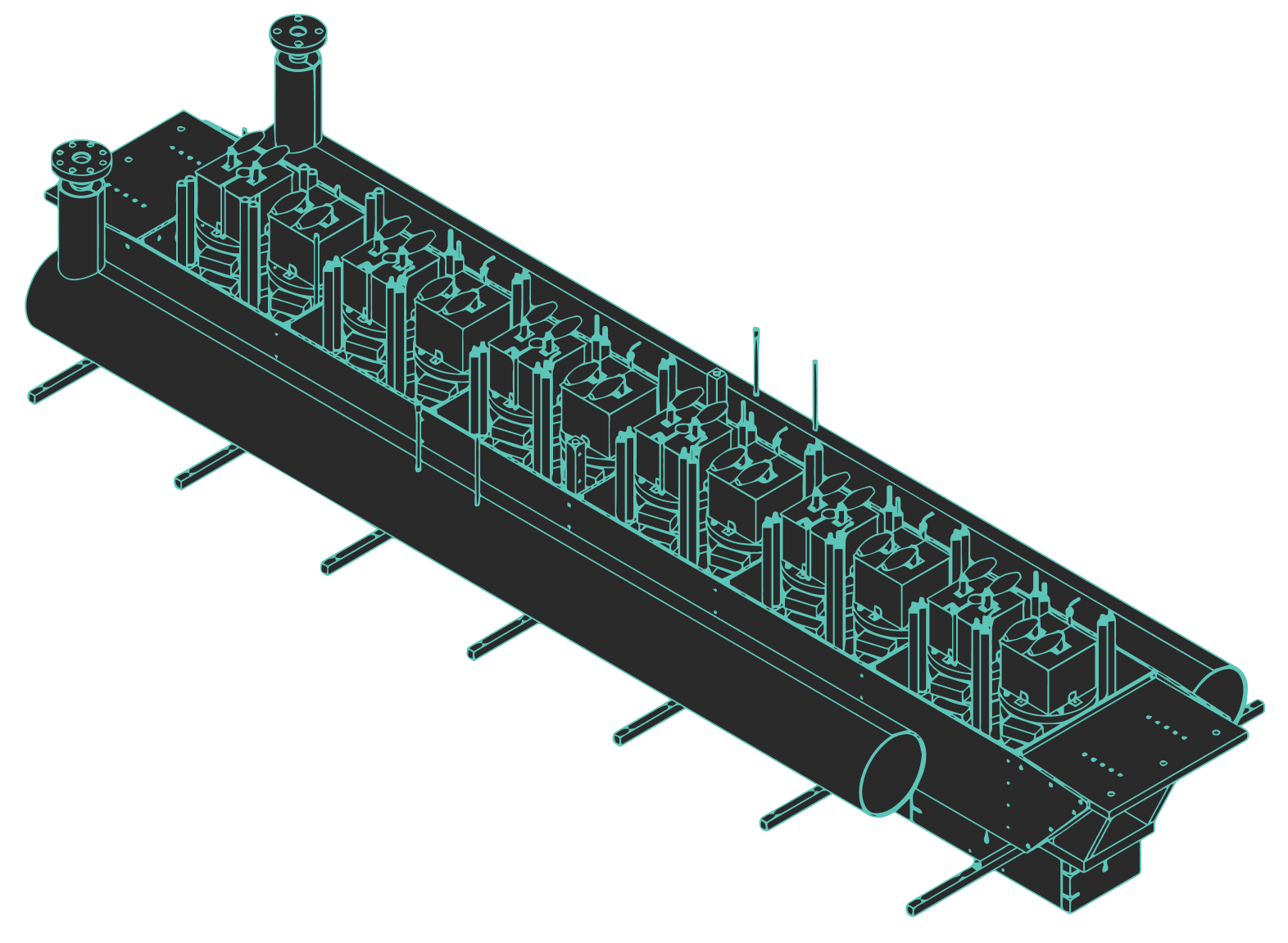

Unlimited potential for varying polymer distribution i.e. cross-section profiles and ratios, within the fibers enabling customization and versatility.