FILAMENT

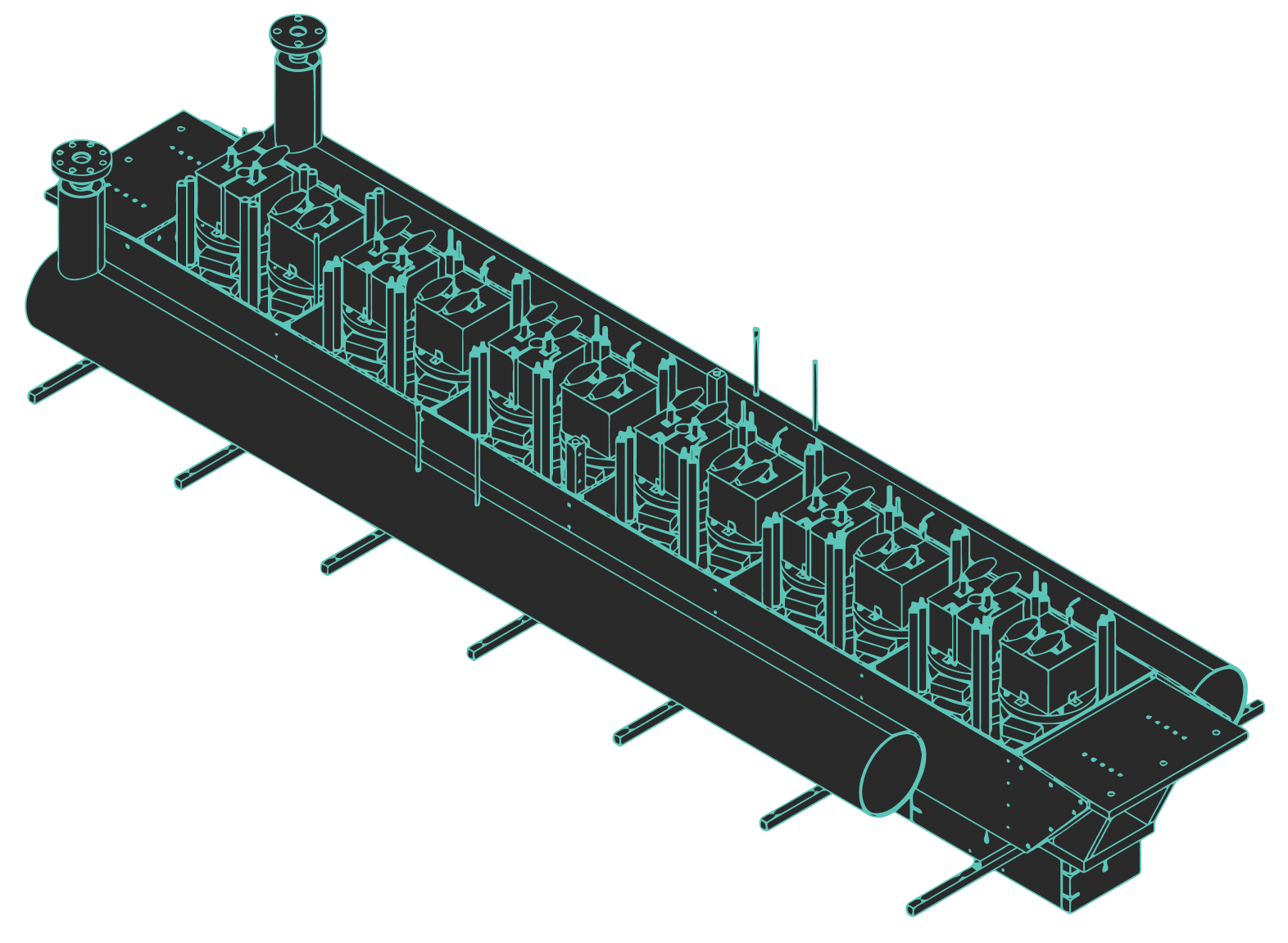

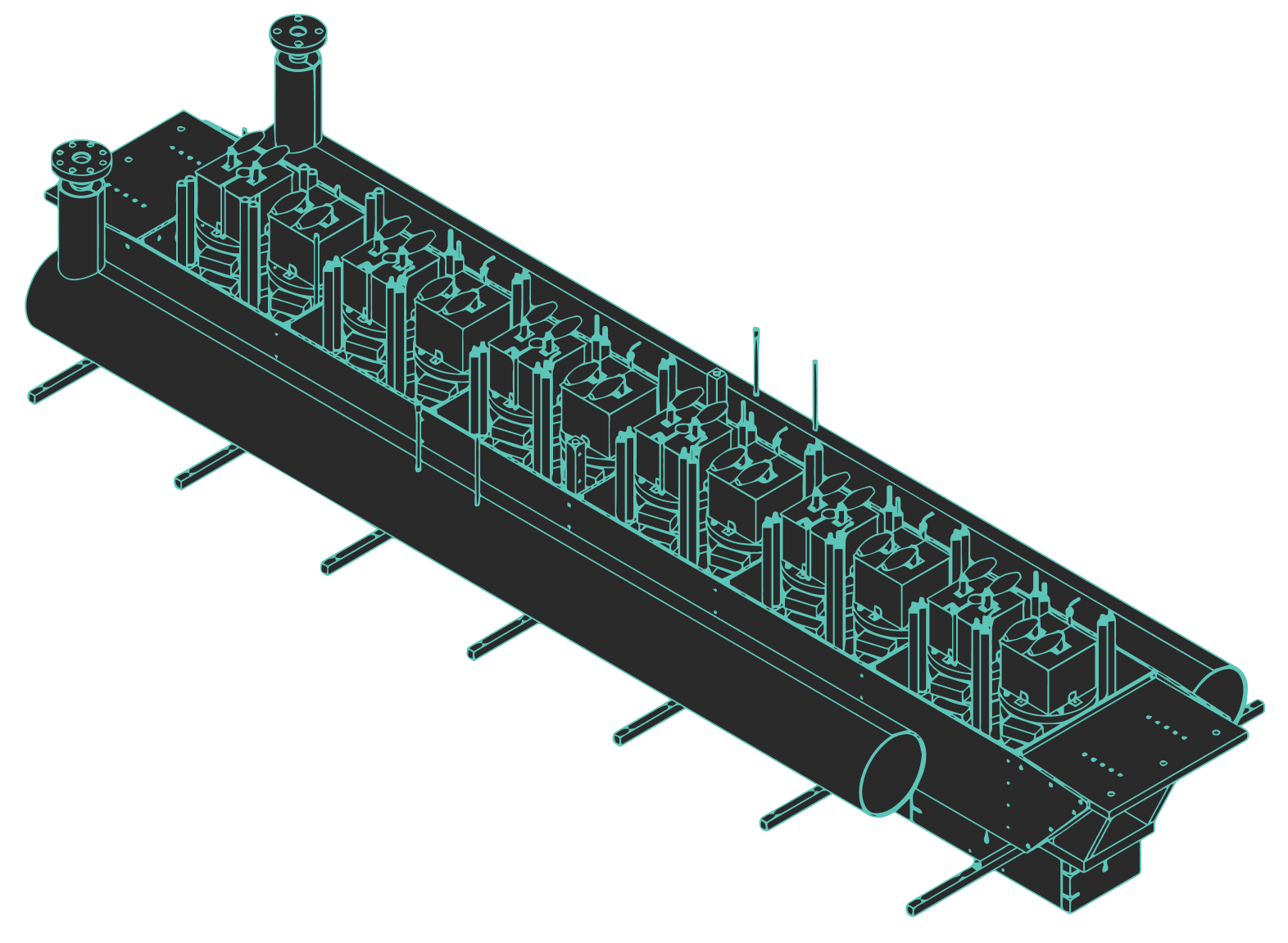

Hills Inc.'s filament fiber extrusion systems are designed for the precision production of continuous filaments with customized cross-sectional profiles and superior mechanical properties. By extruding molten polymer through carefully engineered spinnerets, our technology enables the creation of high-performance fibers used in a wide range of industrial, technical, and textile applications.

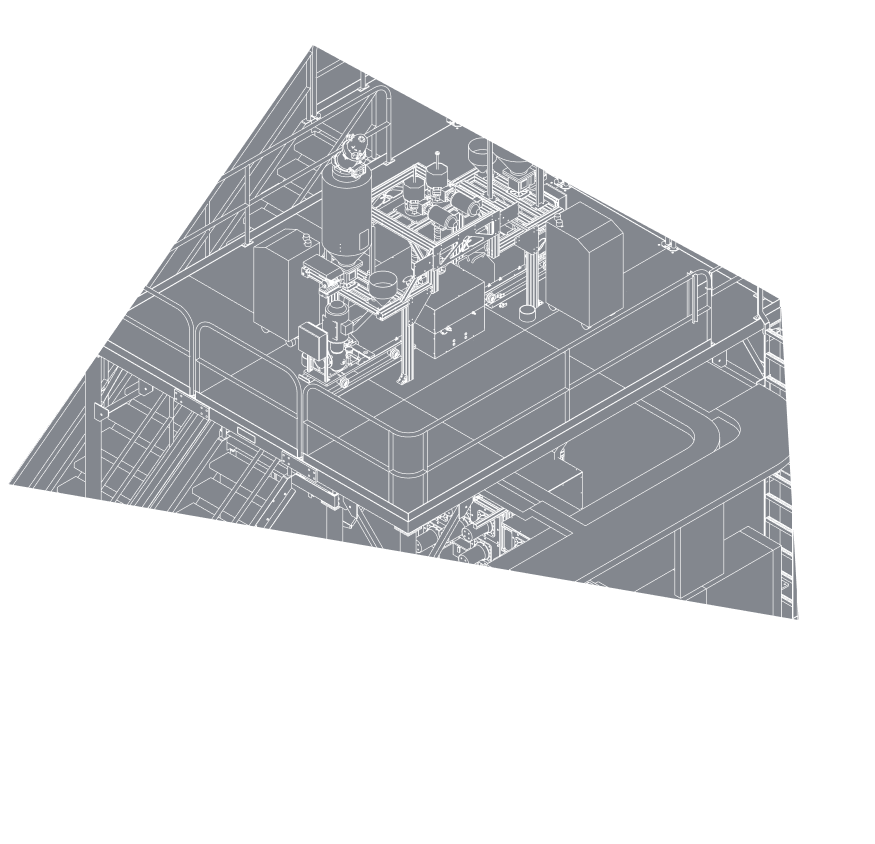

CUSTOM SYSTEM DESIGN

Our modular filament extrusion platforms allow for full customization of spinnerets, quenching zones, godet rolls, and winding systems, enabling the production of filaments with specific diameters, shapes, and properties to meet exact application requirements.

Hills' filament extrusion systems are capable of processing a broad selection of polymers with consistent fiber quality and tight tolerances. This includes traditional polymers as well as advanced, specialty, and biopolymer materials.

- Polypropylene

- Polyamide

- Polyethylene Terephthalate

END-USES

REAL-WORLD PRACTICAL APPLICATIONS

- INDUSTRIAL YARNS

High-tenacity yarns for ropes, nets, and conveyor belts

- TEXTILES

Apparel fabrics, home furnishings, and performance wear

- COMPOSITE REINFORCEMENT

Fiber reinforcements used in automotive, aerospace, and construction

- MEDICAL THREADS

Sutures, implantable textiles, and medical device components

WHY

CHOOSE

HILLS?

Unlimited potential for varying polymer distribution i.e. cross-section profiles and ratios, within the fibers enabling customization and versatility.