MELTBLOWN

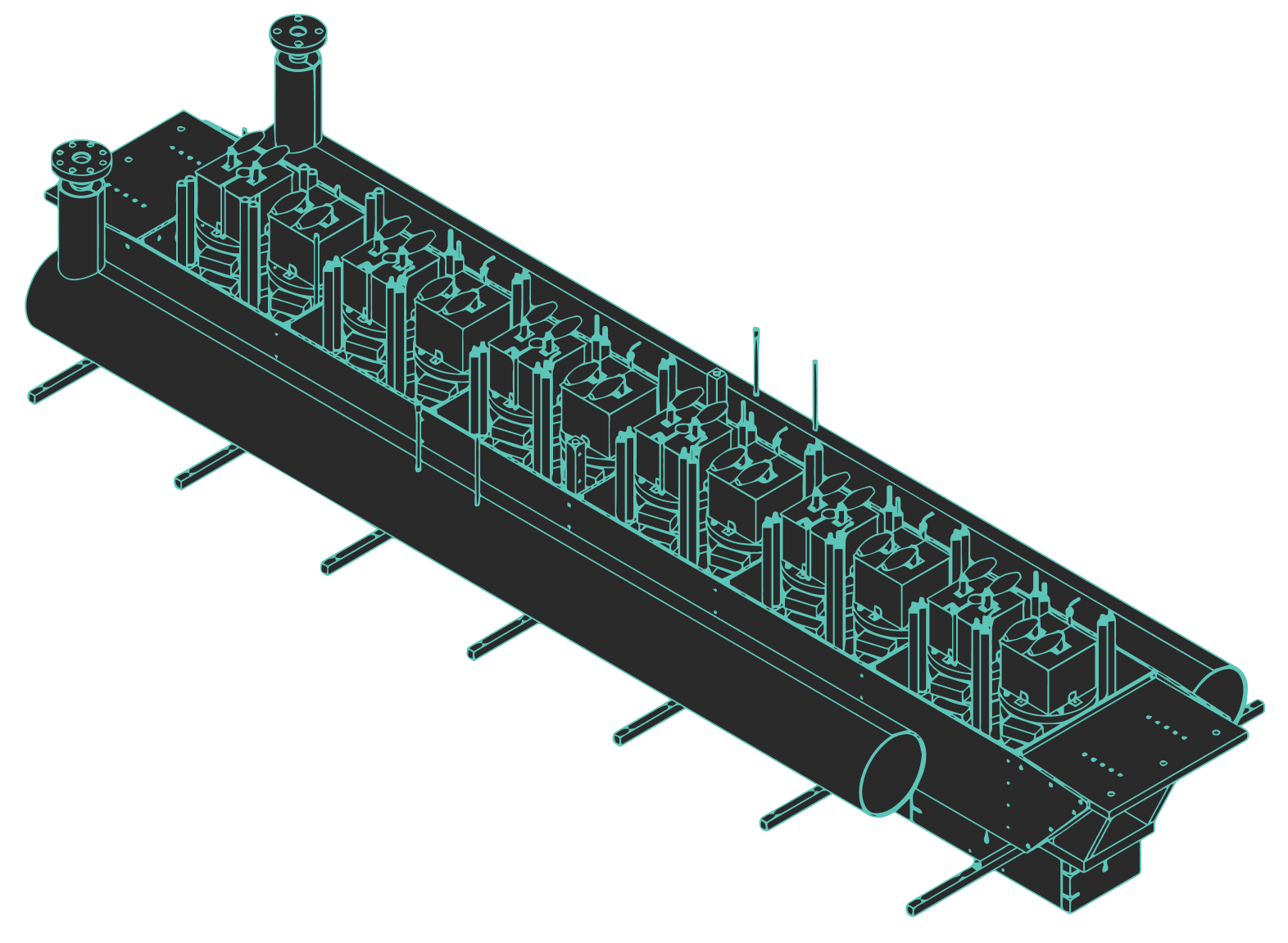

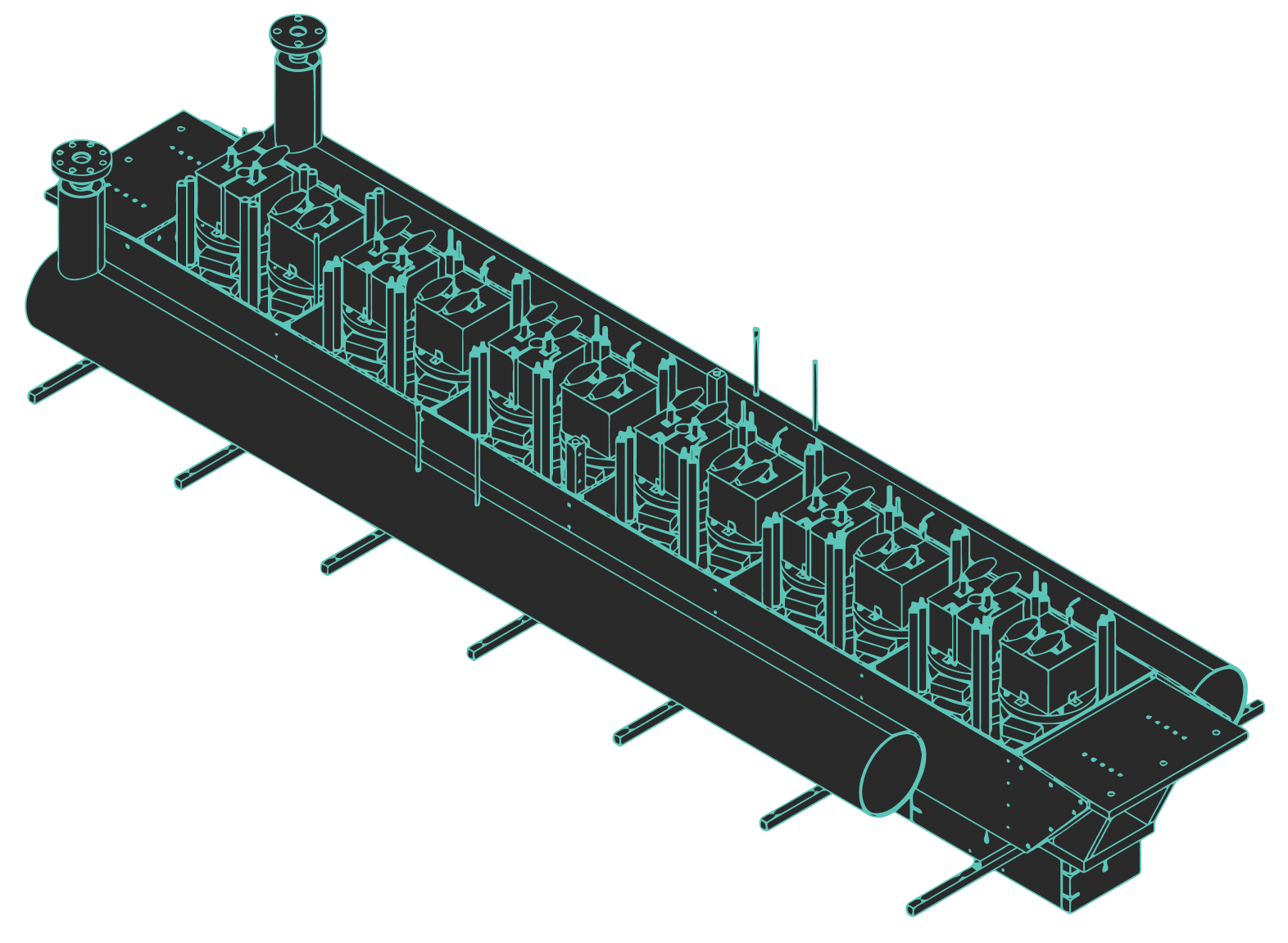

Hills Inc.'s meltblown systems utilize our propietary polymer metering and distribution technology to produce high-quality nonwoven fabrics with fine fibers and tailored properties. By extruding molten polymer through a linear die and attenuating the fibers with high-velocity hot air, meltblown technology creates self-bonding webs.

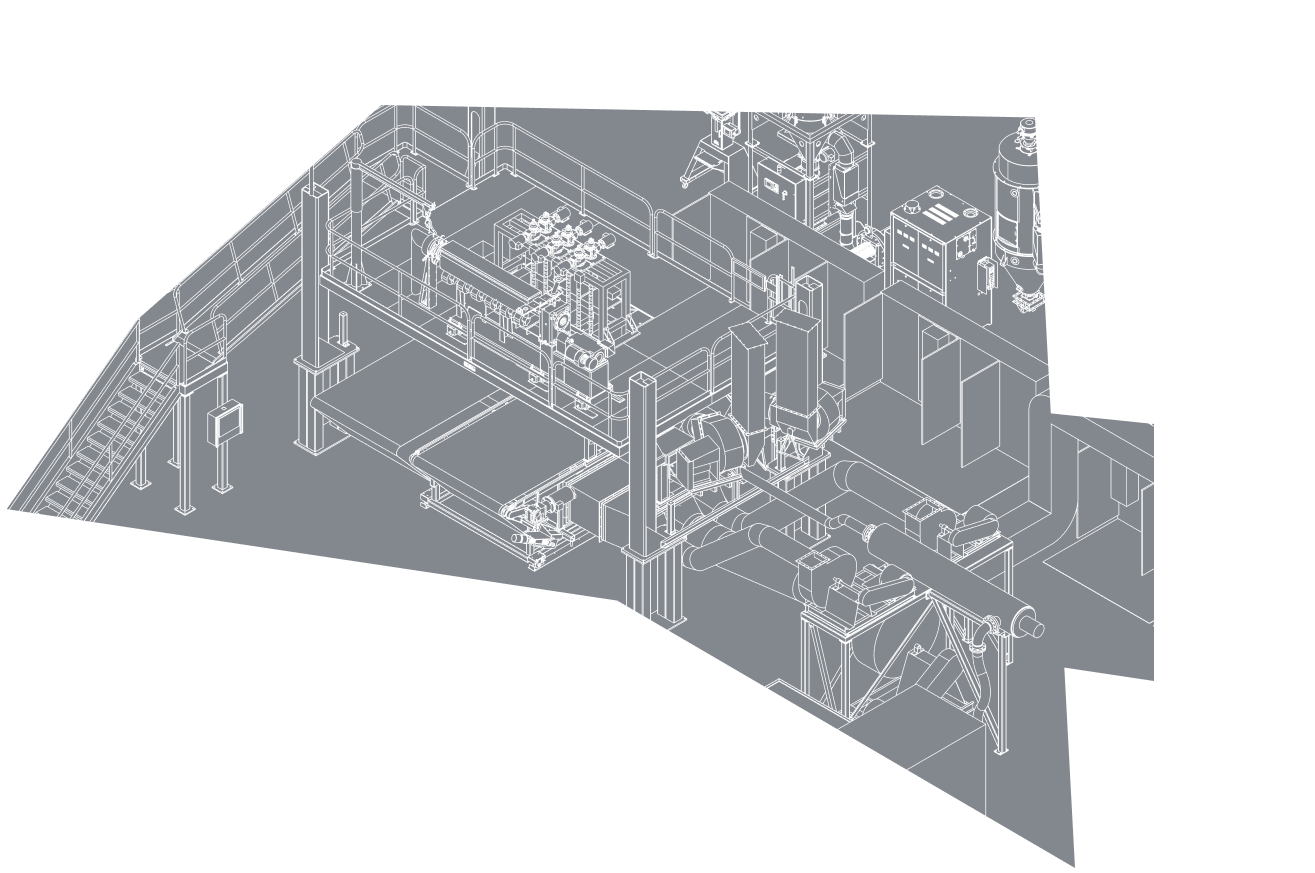

CUSTOM SYSTEM DESIGN

The design of our systems allows for customizable configurations, enabling the production of nonwoven fabrics with specific properties for diverse applications.

Hills' meltblown equipment is engineered to process a wide range of polymers, including those with high viscosity or thermal sensitivity, thanks to precise control over temperature, pressure, and airflow.

- Polypropylene

- Polyethylene

- Polycarbonate

END-USES

REAL-WORLD PRACTICAL APPLICATIONS

- FILTRATION

High-efficiency filtration for air, liquid, and oil

- INSULATION

Thermal and acoustic insulation

- MEDICAL PPE

Breathable barrier fabrics for medical and hygiene products

- INDUSTRIAL CLEANING

Absorbent materials for oil and chemical spills

WHY

CHOOSE

HILLS?

Unlimited potential for varying polymer distribution i.e. cross-section profiles and ratios, within the fibers enabling customization and versatility.